Aluminum Lee .350 Ball Double Cavity Mold – Efficient Bullet Casting

$34.43

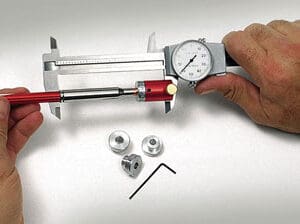

Create perfect round balls with ease using the .350 Ball AluminumLee Double Cavity Mold. This durable aluminum mold ensures precision and consistency in your casting process. A reliable tool for crafting ammunition or fishing weights.

3 in stock

Description

The .350 Ball Aluminum Double Cavity Mold is a precision tool for casting lead balls with consistent roundness and weight for reloading purposes. This mold is made of high-quality aluminum, ensuring durability and efficient heat conduction for smooth casting. The double-cavity design allows for increased productivity by casting two balls simultaneously, saving time and effort during your reloading process. With precise cavity dimensions, this mold produces .350 caliber balls that are ideal for muzzleloader rifles, black powder shooting, or historical reenactments. The smooth aluminum surface ensures easy release of the cast balls, promoting an efficient workflow. The sturdy construction of the mold guarantees long-lasting performance and reliability, making it a valuable addition to any reloading setup. Whether you are a seasoned reloader or a novice enthusiast, the .350 Ball Aluminum Double Cavity Mold offers consistency and quality in your casting operations. Experience enhanced accuracy and performance in your shooting endeavors with perfectly formed lead balls created effortlessly using this reliable and efficient casting mold. Elevate your reloading experience with this premium-quality tool designed to meet the demands of precision shooting and reloading enthusiasts.

Additional information

| Weight | 0.8900 lbs |

|---|---|

| Dimensions | 10.75 × 2.55 × 2.20 in |

| Type/color | 2-cavity |

| Dimension | 2.20 X 2.55 X 10.75 |

| Size/finish | 0.35 |

| Material | Aluminum W/hanldes |

| UPC | 734307904159 |

| MPN | 90415 |

| Brand | Lee |

Reviews

There are no reviews yet.